ITV Boxer 2

EASE OF USE AND EXCEPTIONAL SAFETY LEVEL!

The BOXER 2 was made for Powered Paragliding (PPG) beginners. Its modern design (ILT, 3D shaping, IRS)* and smart choices made by the R&D Dept., contribute to make it easy to untangle the lines and setup the glider. Indeed, 3 risers on each side, and 3 low lines per riser guarantee a trouble free handling of the wing.

The inflation does not require any abrupt gestures, or forceful accompaniment, because the BOXER 2 simply scoops the air and gently climbs overhead. It is much forgiving and will forgive the beginner pilot’s natural gesture approximation.

Once inflated, dampening of the wing is quickly and naturally buffered, only a slight pull on the toggles will be needed during the running phase to takeoff with a smooth gradual lift.

Description

Turning with the BOXER2 is efficiently simple but yet very precise regardless of the important brake travel it has, giving the pilot a true sense of safety. You will appreciate how well balanced its turns are and reactivity is, making it a very pleasant wing to fly, especially in thermal conditions. The BOXER 2 has benefited from all the latest technological advances which made it possible to significantly improve its performance in speed and glide. Its abilities are many, from flying local sites to Cross-Country adventures.

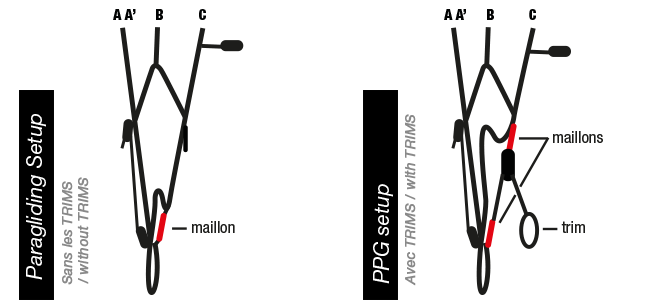

Its risers are equipped with trims which can give the wing a very efficient semi-reflex profile and significantly increases its speed range. The POWER KIT enables the pilot to easily switch from a Powered Paragliding (PPG) to a Paragliding (PG) mode. Simple and quick to disconnect or install using a 2 maillons system without the need for any other extra handling. Flaring with the BOXER2 is particularly efficient for soft PPG landings.

The BOXER2 is DGAC certified, its behavior in flight is a testament to the best passive safety in the our glider lineup.

TECHNICAL DATA :

| BOXER 2 | S | M | L | XL |

|---|---|---|---|---|

| Flat Surface (m²) | 23.0 | 26.0 | 29.0 | 32.0 |

| Weight (kg) | 4.7 | 5.1 | 5.4 | 5.7 |

| Span (m) | 10.5 | 11.02 | 11.8 | 12.4 |

| Chord (m) | 2.65 | 2.85 | 3.00 | 3.20 |

| Aspect ratio | 4.8 | 4.8 | 4.8 | 4.8 |

| Number of cells | 34 | 34 | 34 | 34 |

| Inflight weight range (kg) | 60-113 (DGAC) | 80-140 (DGAC) | 100-166 (DGAC) | 120-200 (DGAC) |

| Trim speed (km/h) | 39 | 39 | 39 | 39 |

| Max speed (km/h) | 49 | 49 | 49 | 49 |

| Certification | DGAC / EN-A | DGAC / EN-A | DGAC / EN-A | DGAC |

POWER KIT SYSTEM

The BOXER 2 is equipped with POWERKIT. This system makes it possible to quickly switch from a paragliding configuration to a paramotor configuration.

*TECHNOLOGY

ILT – LASER TECHNOLOGY: All the precision of LASER cutting of the different parts that make up your ITV wing.

IRS- JONCS REINFORCEMENT SYSTEM: Structural reinforcement of the leading edge through nylons.

3D SHAPING: Optimization of cutting and assembly of the panels that constitute the leading edge.